In today’s marketplace there are several varieties of concrete repair kits and concrete patch kits. There are actual cement/water type kits, acrylic kits, hydraulic cement kits and the list goes on.

The one difference is when you purchase one of the five different versions from the family of TuffPatch kits, you are purchasing a product that is stronger and easier to use than the aforementioned.

Our TuffPatch kits are made of EPC (epoxy polymer concrete) which in testing terms is harder than the concrete it is applied to!

Our TuffPatch kits are made of EPC (epoxy polymer concrete) which in testing terms is harder than the concrete it is applied to!

Here is a brief explanation of what EPC, or TuffPatch kits become when they are applied.

Regular concrete contains sand, water, and Portland cement. When these are combined, they create a pourable mix called concrete. You can see this on almost any concrete pour. This mixture is placed, then troweled into place and then finished. It then has water and curing compounds added to help keep the water in the mixture to prevent early hydration, which could lead to cracking and a weakened surface.

The materials we use in all of our TuffPatch kits are polymer (epoxy or urethane), colorant, and high-quality trowel sand to ease with finishing the patch. It allows our TuffPatch kits to provide a quicker curing product (hours versus days) and provides a higher composite and tensile strength than the concrete it is attached to. It allows repairs to be done very quickly, limiting the downtime. All of the contents you will need are included in each TuffPatch kit. This includes the resin, hardener, pigment and the trowel sand (which is in a plastic bag). This allows our customers to use the clean 5-gallon packaging bucket as a mixing vessel.

In today’s rapid paced environments, cracked concrete, potholes, and sunken or uneven slabs will lead to jeopardizing employee safety, damage to fork trucks, and loss of valuable inventory. Damaged flooring in food and beverage processing areas can lead to fines by inspectors, and the possibility of product contamination.

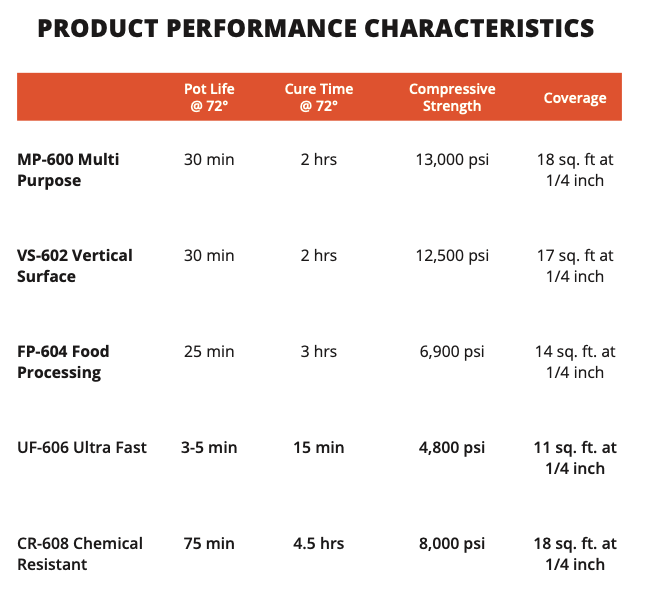

Below is a breakdown comparison of the five versions of our TuffPatch Kits.